Custom design solutions available for bespoke needs. Learn More

My Cart:

Custom design solutions available for bespoke needs. Learn More

My Cart:

Introduction

The foundation of any furniture piece, literally and figuratively, is its structural approach. While most furniture manufacturers focus on aesthetics, cost, or basic functionality, safety furniture requires a fundamentally different engineering philosophy. The choice between traditional frame-based construction and solid foam engineering determines not just safety outcomes, but comfort, durability, maintenance requirements, and long-term value.

After over a decade of manufacturing sensory safety furniture, we’ve learned that the construction method is the single most important factor in creating furniture that truly serves care and custodial environments. The differences between solid foam and traditional construction methods reveal why many facilities struggle with furniture that meets basic safety requirements but fails to deliver the reliability, comfort, and longevity that care environments demand.

The Traditional Construction Dilemma

Most furniture, including much of what’s marketed as “safety furniture” relies on traditional frame-based construction: wooden or metal frames, springs or webbing for support, foam cushioning, and fabric or vinyl coverings. This approach works well for residential and commercial environments where safety requirements are minimal and usage patterns predictable.

However, care and custodial environments present unique challenges that expose the limitations of traditional construction:

Component Interdependence Traditional furniture depends on multiple components working together. Frames provide structure, springs offer support, cushioning adds comfort, and coverings protect and beautify. When any component fails, the entire piece is compromised.

Connection Vulnerabilities

Traditional construction requires joints, fasteners, and attachment points, each represents a potential failure mode. Over time, connections loosen, joints separate, and attachment points weaken.

Material Degradation Patterns Different materials age at different rates and respond differently to cleaning chemicals, temperature variations, and usage stress. This creates uneven wear patterns and unpredictable failure modes.

Maintenance Complexity Traditional furniture requires ongoing maintenance of multiple components: tightening connections, replacing worn springs, repairing fabric damage, and addressing frame issues. Each maintenance need creates downtime and safety concerns.

The Solid Foam Engineering Revolution

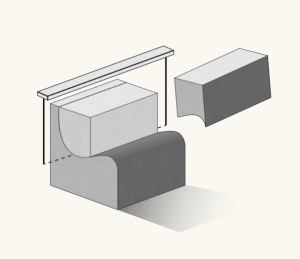

Solid foam construction represents a completely different approach to furniture engineering. Rather than assembling multiple components, solid foam furniture is carved from high-density foam blocks specifically engineered for safety furniture applications.

This seemingly simple difference creates profound advantages:

Structural Integrity Solid foam furniture has no joints, connections, or assembly points that can fail. The entire piece is a single structural unit with consistent strength throughout.

Elimination of Failure Points With no removable components, loose connections, or degrading joints, solid foam furniture eliminates the most common causes of safety furniture failure.

Consistent Performance Over Time Solid foam maintains its structural integrity and safety characteristics throughout its lifecycle. There’s no gradual degradation of connections or components that could create new safety risks.

Simplified Maintenance Profile

Solid foam furniture requires only surface cleaning and periodic inspection. There are no mechanical components to maintain, adjust, or replace.

Engineering Deep Dive: Foam Science and Safety

Not all foam is suitable for safety furniture applications. The foam used in Abecca furniture undergoes extensive engineering to optimise multiple performance characteristics:

Density and Compression Resistance Our foam is engineered to specific density requirements that provide firm, consistent support while maintaining comfort. The compression resistance ensures the furniture maintains its shape and safety characteristics under heavy use.

Cell Structure and Durability The cellular structure of safety furniture foam is optimised for longevity and consistent performance. Closed-cell construction prevents moisture absorption while maintaining structural integrity over decades of use.

Chemical Resistance and Cleanability Safety furniture foam must withstand repeated exposure to disinfectants without degrading. We supply a recommended list of products. Our foam formulation maintains its structural and safety properties.

Fire Resistance and Safety Compliance All foam meets or exceeds fire safety requirements for institutional furniture, including BS7177 & Crib 7. Fire resistance is inherent in the foam chemistry, not dependent on chemical treatments that can degrade over time.

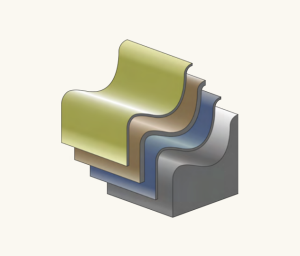

Surface Integration: The LimberShield® Advantage

Traditional furniture coverings, whether fabric or vinyl are applied over cushioning and attached to frames. This creates seams, attachment points, and potential separation areas that compromise both safety and durability.

LimberShield® technology represents a breakthrough in surface integration. Rather than covering foam with separate materials, our thermo-fusion process creates seamless surface integration:

Molecular-Level Bonding The LimberShield® surface becomes part of the foam structure itself, not a separate covering that could separate, lift, or be removed.

Elimination of Seams and Attachment Points Traditional furniture coverings require seams, zips, or attachment methods that create potential ligature points. LimberShield® surfaces are completely seamless.

Superior Durability Because the surface is integrated rather than attached, there’s no wear at attachment points or gradual separation that occurs with traditional coverings.

Enhanced Cleanability Seamless surfaces have no crevices, seams, or attachment points where contaminants can accumulate. This enables more thorough cleaning and better infection control.

Performance Comparison: Real-World Testing

To demonstrate the advantages of solid foam construction, we conduct extensive comparison testing between our solid foam furniture and traditional frame-based safety furniture:

Safety Integrity Over Time

Maintenance Requirements

Cleanability and Infection Control

Cost Analysis: Initial Investment vs. Lifecycle Value

While solid foam construction typically requires higher initial investment than traditional furniture, lifecycle cost analysis reveals significant economic advantages:

Maintenance Cost Elimination Traditional safety furniture requires ongoing maintenance costs annually. Solid foam furniture maintenance costs are essentially zero after initial purchase.

Replacement Cycle Extension Traditional safety furniture typically requires replacement every 5-7 years due to component failure or safety degradation. Quality solid foam furniture maintains safety and appearance for 10+ years.

Incident Cost Reduction Facilities using solid foam construction report considerably fewer furniture-related safety incidents compared to traditional frame construction, significantly reducing incident management costs.

Operational Efficiency Improvements Simplified cleaning and maintenance requirements reduce housekeeping time, while elimination of furniture-related maintenance calls improves operational efficiency.

Environmental Impact and Sustainability

Solid foam construction also offers environmental advantages that align with modern sustainability goals:

Extended Product Lifecycle Longer furniture lifecycles reduce replacement frequency, decreasing overall environmental impact and waste generation.

Simplified Recycling Single-material construction simplifies end-of-life recycling compared to traditional furniture with multiple material types requiring separate processing.

Reduced Maintenance Chemical Usage Elimination of complex maintenance requirements reduces ongoing chemical usage for cleaning and treatment.

Manufacturing Efficiency Solid foam manufacturing processes are generally more energy-efficient than traditional furniture assembly operations.

Implementation Considerations for Facilities

Transitioning from traditional to solid foam construction requires understanding the differences and planning accordingly:

Staff Training and Expectations Staff accustomed to traditional furniture may need education about solid foam advantages and proper care procedures.

Aesthetic Integration Solid foam furniture may look different from traditional pieces, requiring consideration of overall environmental design goals.

Budget Planning Higher initial investment requires understanding of lifecycle cost benefits and appropriate budget planning for long-term value realisation.

https://abeccadesign.com/product-category/safe-furniture/armadillo-range/

The Future of Safety Furniture Construction

As our understanding of safety requirements, material science, and manufacturing processes continues advancing, solid foam construction will likely become the standard for all safety furniture applications. Current research focuses on:

Conclusion

Material choice and construction method are fundamental decisions that determine every aspect of furniture performance in care and custodial environments. While traditional frame-based construction may appear familiar and initially less expensive, the limitations become evident over time through maintenance requirements, safety concerns, and replacement needs.

Solid foam construction with integrated LimberShield® surfaces represents an evolution in safety furniture engineering that addresses the root causes of traditional furniture problems. By eliminating failure modes rather than managing them, solid foam construction provides the reliability, safety, and long-term value that care environments require.

The choice isn’t just between different furniture construction methods it’s between furniture that requires constant attention and furniture that provides consistent performance, between furniture that creates ongoing costs and furniture that delivers lasting value, between furniture that compromises and furniture that excels.

In environments where furniture failure can have serious consequences, the engineering approach that eliminates rather than manages failure modes isn’t just better, it’s essential.

Share this Article